Supplemental Oxygen Requirements:

- As pressure altitude increases, the partial pressure of oxygen (also known as O2) decreases

- This decrease in partial pressure prohibits oxygen saturation into the blood

- Therefore oxygen requirements are reference pressure altitude

- Effects of oxygen deprivation:

- Above 10,000', the crew may begin to make errors in judgment, mental alertness diminishes

- Above 15,000', collapse and unconsciousness are not uncommon (hypoxia)

- At 40,000', death will occur in approximately 8 to 12 seconds

- Therefore, the required oxygen schedule is:

- Sea Level to 12,500' - No oxygen required

- 12,501' to 14,000' - Required by the required crew if over 30 minutes at this altitude

- 14,001' to 15,000' - Required to be provided and used by the required flight crew

- 15,001' to 25,000' - Must be provided for every occupant

- 25,001' to Unlimited - Required to satisfy the above and an additional 10 minutes for each occupant

- At FL350 - if one pilot leaves the cockpit then the other must utilize supplemental oxygen on unless he has a quick donning mask

- At FL410 - each pilot must be on oxygen at all times

- Oxygen requirements are in Federal Aviation Regulation 91.211

- Regulators approved for use up to 40,000' are designed to provide zero percent cylinder oxygen and 100% cabin air at cabin altitudes of 8,000' or less, with the ratio changing to 100% oxygen and zero percent cabin air at approximately 34,000' cabin altitude [Figure 1]

- Regulators approved up to 45,000' are designed to provide 40% cylinder oxygen and 60% cabin air at lower altitudes, with the ratio changing to 100% at the higher altitude

- Pilots should avoid flying above 10,000' without oxygen during the day and above 8,000' at night

- Smoking during any oxygen equipment use is prohibited

- Before each flight, the pilot should thoroughly inspect and test all oxygen equipment

- When inspecting, make sure your hands are clean of oils and greases, which may ignite if exposed to oxygen

- After any oxygen use, verify that all components and valves are closed

Aircraft Oxygen System Designs:

- There are a variety of different oxygen systems and delivery methods available to general and commercial aviation, including:

-

Chemical Oxygen:

- Generally used on large aircraft in case of an emergency to provide a 10 minute supply of oxygen

- Activated by a lanyard on the oxygen mask, as the user pulls the mask to their face, a chemical reaction with sodium chlorate is triggered

- Once this system is activated, it must burn out, requiring replacement

- Chemical oxygen is lightweight and compact

- Oxygen tanks are normally green in color

- Oxygen candles used on airliners

- No more than 0.005 ml of water per 1 liter of oxygen = 99.5% O2

-

Portable Gaseous Oxygen Systems:

- Portable gaseous oxygen system provides oxygen when required for aircraft which lack an integral oxygen system

- These systems are used for passengers or crew members when the aircraft oxygen systems services only the pilot and copilot, or when the duties of the crew require them to move about the aircraft

- A portable unit weighs approximately 20 pounds and typically consists of: lightweight steel oxygen cylinder (usually 1800 Pounds per Square Inch (PSI), capacity vary), associated plumbing, combined flow control/reducing valve pressure gauge, and a breathing mask and connecting hose

- Portable equipment usually consists of:

- Container

- Regulator

- Mask outlet

- Pressure gauge

-

On-Board Oxygen Generating Systems:

- On-Board Oxygen Generating System, or OBOGS, converts engine compressor bleed air to oxygen-rich breathing air and pressurized air for at the correct pressure and temperature

- OBOGS provides a continuous supply of breathing air for crew while the engine is operating

- Components consist of a heat exchanger, concentrator, regulator, and associated plumbing

-

Liquid Oxygen Systems:

- Liquid oxygen systems, or LOX, is used in some jet aircraft because LOX storage occupies less space and weigh less than those used for gaseous oxygen

- LOX systems typically consists of converters, check valves and manifolds, oxygen heat exchanger, oxygen/vent airflow control panel, liquid quantity indicator, and a breathing mask with connecting hoses

Supplemental Oxygen Delivery Systems:

- There are numerous types and designs of oxygen masks in use

- The most critical factor in oxygen mask use is to ensure the masks and oxygen system are compatible

- Crew masks are fitted to the user's face with a minimum of leakage and usually contain a microphone

- Most masks are the oronasal type, which covers only the mouth and nose

- A passenger mask may be a simple, cup-shaped rubber molding sufficiently flexible to prevent individual fitting

- It may have a simple elastic head strap, or the passenger may hold it to his or her face

- All oxygen masks should be clean to reduce the danger of infection and prolong the life of the mask

- To clean the mask, wash it with a mild soap and water solution and rinse it with clear water

- If a containing a microphone, use a clean swab, instead of running water, to wipe off the soapy solution

- The mask should also be disinfected

- A gauze pad that has been soaked in a water solution of Merthiolate can be used to swab out the mask

- This solution used should contain a one-fifth teaspoon of Merthiolate per quart of water

- Wipe the mask with a clean cloth and air dry

- Both pressure and diluter-demand systems use a diaphragm operated demand valve, which opens when suction from inhalation is present

- This makes the system more efficient

-

Cannula:

- A cannula is an ergonomic piece of plastic tubing that runs under the nose and is often used to administer oxygen in non-pressurized aircraft [Figure 2]

- Cannulas are typically more comfortable than masks and can be used up to 18,000'

- Not authorized above 18,000'; therefore, altitudes greater than 18,000' require the use of an oxygen mask

- Many cannulas have a flow meter in the line, and if equipped, a periodic check of the green flow detector should be part of a pilot's regular scan

-

Continuous-Flow Oxygen System:

- Passenger aircraft generally utilize continuous-flow oxygen systems

- The passenger mask typically has a reservoir bag, which collects oxygen from the continuous-flow oxygen system when the mask user is exhaling

- The oxygen collected in the reservoir bag allows a higher aspiratory flow rate during the inhalation cycle, which reduces the amount of air dilution

- Ambient air is added to the supplied oxygen during inhalation after the reservoir bag oxygen supply is depleted

- The exhaled air releases to the cabin [Figure 3]

-

Electrical Pulse-Demand Oxygen System:

- Portable electrical pulse-demand oxygen systems deliver oxygen by detecting an individual's inhalation effort and provide oxygen flow during the initial portion of inhalation

- Pulse demand systems do not waste oxygen during the breathing cycle because oxygen only delivers during inhalation

- Compared to continuous-flow systems, the pulse-demand method of oxygen delivery can reduce the amount of oxygen needed by 50-85%

- Most pulse-demand oxygen systems also incorporate an internal barometer that automatically compensates for changes in altitude by increasing the amount of oxygen delivered for each pulse as altitude is increased [Figure 4]

-

Continuous Flow:

- Usable up to 25,000'

- Provide a constant delivery of oxygen

- Cost-efficient and simple operation

-

Constant-Flow:

- Delivers a constant amount of O2, inefficient at low altitudes

- Adjustable-flow: Increases O2 duration by allowing the user to adjust a regulator valve for different altitudes manually

- Altitude-compensated: Works like adjustable-flow, but utilizes barometric pressure to adjust O2 for changing altitudes automatically

- These systems can be either built in or portable

- Oronasal re-breathers: cover both nose and mouth and use a re-breather bag to mix oxygen and exhaled air

- Cannula, which inserts into the nose

- As altitude increases, the ratio of O2 in the bag increases because of decreased ambient air pressure

- Check valves allow for exhaled air to exit the mask at high altitudes completely

- General flow rates are 120 liters per hour for crew and 90 liters per hour for passengers

-

Diluter-Demand:

- Diluter-demand oxygen systems supply oxygen only when the user inhales through the mask

- An auto-mix lever allows the regulators to automatically mix cabin air and oxygen or supply 100% oxygen, depending on the altitude

- The demand mask provides a tight seal over the face to prevent dilution with outside air

- Diluter-demand provides sufficient O2 up to 40,000'

- A pilot who has a beard or mustache should ensure it will not interfere with the sealing of the oxygen mask

-

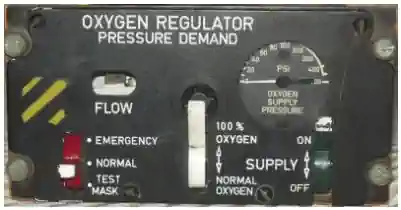

Pressure-Demand:

- Pressure-demand oxygen systems are similar to diluter demand oxygen equipment, except that oxygen is supplied to the mask under pressure at cabin altitudes above 34,000'

- Pressure-demand regulators create airtight and oxygen-tight seals, but they also provide a positive pressure application of oxygen to the mask facepiece that allows the user's lungs to pressurize with oxygen

- Pressure-demand is used above 40,000' because even with 100% O2, the atmospheric pressure is too low to allow proper saturation into the bloodstream

- Some systems may have a pressure-demand mask with the regulator attached directly to the mask rather than mounted on the instrument panel or other area within the flight deck

- The mask-mounted regulator eliminates the problem of a long hose that must be purged of air before 100% oxygen begins flowing into the mask

Supplemental Oxygen System Components:

-

Oxygen Containers:

- Containers (tanks) are green in color

- Aircraft oxygen stores in high-pressure system containers of 1,800-2,200 PSI

- When the ambient temperature surrounding an oxygen cylinder decreases, the pressure within that cylinder decreases because pressure varies directly with temperature if the volume of a gas remains constant

- If indicated pressure on a supplemental oxygen cylinder drops, there is no reason to suspect depletion of the oxygen supply, which has compressed due to storage of the containers in an unheated area of the aircraft

- High-pressure oxygen containers have markings with the psi tolerance (i.e., 1,800 psi) before filling the container to that pressure

- Service containers with aviation oxygen only, which is 100% pure oxygen

- Industrial oxygen is not intended for breathing and may contain impurities, and facepiece oxygen masks may contain water vapor that can freeze in the regulator when exposed to cold temperatures

- To assure safety, pilots should do periodic inspection and servicing of the oxygen system

Safety Precautions:

- Oxygen is an oxidizer, supporting combustion, and an extremely hazardous material in the aviation environment

- Acting as a catalyst, small sparks or fires in the presence of combustibles such as oils, fuels, and other chemicals can quickly grow

- Purge hoses before coupling to aircraft filler valves to avoid contamination

- Containers need to be filled in a controlled manner to avoid overheating

- Keep oil and grease away from oxygen equipment, including tools and protective clothing to avoid contamination

- Use spark-free tools (brass) when servicing oxygen systems

- Do not open valves of an oxygen system or cylinder when a flame, electrical arc, or any other source of ignition is in the immediate area

- Take extreme caution not to touch implements containing liquid oxygen without gloves due to the extremely low temperature

- Use protective clothing when working with LOX including gloves, coveralls, face shields, and LOX boots

- Never seal or cap the vent port of a LOX system

- Vent design ensures sufficient flow capacity to carry away LOX that may escape

- The expansion ratio of liquid oxygen is 862 to 11-liquid oxygen at atmospheric pressure will a generate pressure of up to 12,000 PSI

- If allowed to evaporate in a sealed container or system which has no relief provisions, LOX could cause an explosion

- Never saturate cloth, wood, grease, oil paint, or tar with LOX

- LOX by itself will not burn, but mixing it with any material will cause the LOX to boil and splash violently with possible combustion

Pulse Oximeters:

- A pulse oximeter is a device that measures the amount of oxygen in an individual's blood, in addition to heart rate

- This non-invasive device measures the color changes that red blood cells undergo when they become saturated with oxygen

- By transmitting a special light beam through a fingertip to evaluate the color of the red cells, a pulse oximeter can calculate the degree of oxygen saturation within one percent of directly measured blood oxygen

- Because of their portability and speed, pulse oximeters are very useful for pilots operating in non-pressurized aircraft above 12,500' where supplemental oxygen is required

- A pulse oximeter permits crew-members and passengers of an aircraft to evaluate their actual need for supplemental oxygen [Figure 5]

- Remember, as oxygen saturation drops below 90%, you've entered the first stages of hypoxia's debilitating effects

O2 Preflight Checklist:

- Pilots must always check aircraft oxygen systems for accessibility inflight and operational function

- An easy acronym to remember how is "PRICE:

- Pressure

- Regulator (check quantity)

- Indicators

- Connections

- Emergency

Oxygen System Servicing:

- Before servicing any aircraft with oxygen, consult the specific aircraft service manual to determine the type of equipment required and procedures to be used

- Observe precautions whenever servicing aircraft oxygen systems

- Oxygen system servicing should be accomplished only when the aircraft is outside of the hangars

- Personal cleanliness and good housekeeping are imperative when working with oxygen

- Oxygen under pressure and petroleum products create spontaneous results when in contact with each other

- Service people should be certain to wash dirt, oil, and grease (including lip salves and hair oil) from their hands and tools before working around oxygen equipment

- Aircraft with permanently installed oxygen tanks usually require two persons to accomplish servicing of the system

- One should remain at the service equipment control valves, with the others located where he or she can observe the aircraft system pressure gauges

- Oxygen system servicing is not recommended during aircraft fueling operations or while other work is performed that could provide a source of ignition

- Oxygen system servicing while passengers are on board the aircraft is not recommended

SCUBA Diving Recommendations:

- A pilot or passenger who intends to fly after scuba diving should allow the body sufficient time to rid itself of excess nitrogen absorbed during diving

- Decompression sickness can occur from evolved gas creating a serious in-flight emergency

-

8,000' MSL and below:

- The recommended waiting time before going to flight altitudes of up to 8,000 feet is at least 12 hours after diving which has not required controlled ascent (non-decompression stop diving), and at least 24 hours after diving which has required controlled ascent (decompression stop diving)

-

Above 8,000' MSL:

- The waiting time before going to flight altitudes above 8,000 feet should be at least 24 hours after any SCUBA dive

- These recommended altitudes are actual flight altitudes above mean sea level (AMSL) and not pressurized cabin altitudes

- This takes into consideration the risk of decompression of the aircraft during flight

Private Pilot - Operation of Aircraft Systems Airman Certification Standards:

- To determine that the applicant exhibits satisfactory knowledge, risk management, and skills associated with the safe operation of systems on the airplane provided for the flight test

- References: FAA-H-8083-2, FAA-H-8083-3, FAA-H-8083-23, FAA-H-8083-25; POH/AFM

- Lesson Plan

Operation of Aircraft Systems Knowledge:

The applicant must demonstrate an understanding of:PA.I.G.K1:

Airplane systems, to include: (Note: If K1 is selected, the evaluator must assess the applicant's knowledge of at least three of the following sub-elements)-

PA.I.G.K1a:

Primary flight controls -

PA.I.G.K1a:

Secondary flight controls -

PA.I.G.K1c:

Powerplant and propeller -

PA.I.G.K1d:

Landing gear -

PA.I.G.K1e:

Fuel, oil, and hydraulic -

PA.I.G.K1f:

Electrical -

PA.I.G.K1g:

Avionics -

PA.I.G.K1h:

Pitot-static, vacuum/pressure, and associated flight instruments -

PA.I.G.K1i:

Environmental -

PA.I.G.K1j:

Deicing and anti-icing -

PA.I.G.K1k:

Water Rudders -

PA.I.G.K1l:

Oxygen Systems

-

PA.I.G.K2:

Indications of and procedures for managing system abnormalities or failures

Operation of Aircraft Systems Risk Management:

The applicant demonstrates the ability to identify, assess, and mitigate risks, encompassing:PA.I.G.R1:

Failure to detect system malfunctions or failuresPA.I.G.R2:

Improper management of a system failurePA.I.G.R3:

Failure to monitor and manage automated systems

Operation of Aircraft Systems Skills:

The applicant demonstrates the ability to:PA.I.G.S1:

Operate at least three of the systems listed in K1a through K1l above appropriatelyPA.I.G.S2:

Use appropriate checklists properly

Supplemental Oxygen Case Studies:

- NTSB Identification: WPR12FA154: The National Transportation Safety Board determines the probable cause(s) of this accident to be: The in-flight loss of control due to the pilot's impairment as a result of hypoxia. Contributing to the accident was the pilot's operation of the airplane above 12,500' without the aid of supplemental oxygen

- NTSB Identification: CEN09LA527: The National Transportation Safety Board determines the probable cause(s) of this accident to be: The in-flight loss of control due to the pilot's impairment as a result of hypoxia. Contributing to the accident was the pilot's decision to operate the unpressurized airplane at an altitude requiring supplemental oxygen without having any oxygen available

Supplemental Oxygen Knowledge Quiz:

Conclusion:

- Note that while the percentage of oxygen in the atmosphere does not decrease, pressure for the body to absorb it does, necessitating supplemental oxygen

- Note the connection between supplemental oxygen and hypoxia in our case studies

- These rules are in place because others have died from it

- At night, especially when tired, these effects may occur as low as 5,000 feet

- Therefore, for optimum protection, pilots are encouraged to use supplemental oxygen above 10,000 feet cabin altitude during the day and above 5,000 feet at night

- Be sure you're following your Pilot Information Manual as applicable for the appropriate use of oxygen systems

- While subjective, oxygen use when operating near the required altitudes for it may also improve alertness and therefore decision making

- Realize that while operating near, but below, altitudes requiring oxygen, passengers may still find themselves experiencing distress without it

- Still looking for something? Continue searching:

References:

- Advisory Circular (61-107) Aircraft Operations at Altitudes Above 25,000 Feet Mean Sea Level or Mach Numbers Greater Than .75

- Aeronautical Information Manual (8-1-2) Effects of Altitude

- Federal Aviation Administration - Oxygen Equipment Use in General Aviation Operations

- Federal Aviation Administration - Pilot/Controller Glossary

- Federal Aviation Regulations (91.211) Supplemental Oxygen

- Flying and Diving - A Unique Health Concern

- Pilot Handbook of Aeronautical Knowledge (6-34) Oxygen Systems