Lubrication Systems:

- Lubrication systems consist of either a wet-sump or Dry-sump system

- The difference between the two systems can be remembered as if the engine were off

- Wet sump systems maintain oil in reservoirs integral to the engine while dry sumps do not, leaving the sump "dry"

-

Wet-Sump:

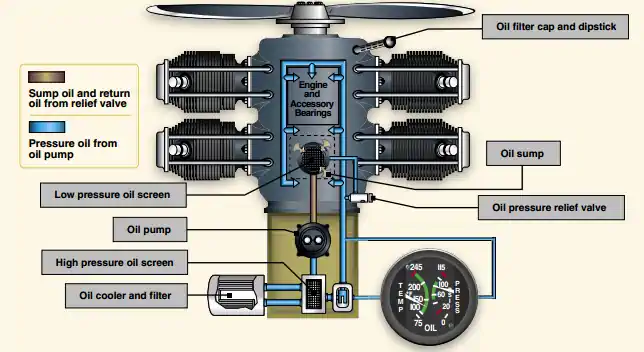

- Oil is carried in a sump, which is an integral part of the engine [Figure 2]

- The main component is the oil pump, which draws oil from the sump and routes it to the engine

- After the oil passes through the engine, it returns to the sump

- In some engines, additional lubrication is supplied by the rotating crankshaft, which splashes oil onto portions of the engine

-

Dry-Sump:

- Oil is contained in a separate tank, and circulated through the engine by pumps

- These tanks are always larger than the oil it is meant to contain to compensate for thermal expansion

- An oil pump also supplies oil pressure in a dry-sump system, but the source of the oil is located external to the engine in a separate oil tank

- After oil is routed through the engine, it is pumped from the various locations in the engine back to the oil tank by scavenge pumps

- Dry-sump systems allow for a greater volume of oil to be supplied to the engine, which makes them more suitable for very large reciprocating engines

- Most jet engines will consist of a dry sump design

- When checking the oil level on an dry-sump engine that has been sitting idle, readings may be inaccurate unless rotated (or "burped")

- Refer to your POH

- The oil filler cap/dipstick used to measure oil quantity is usually accessible through a panel in the engine cowling [Figure 2]

- If the quantity does not meet the manufacturer's recommended operating levels, oil should be added

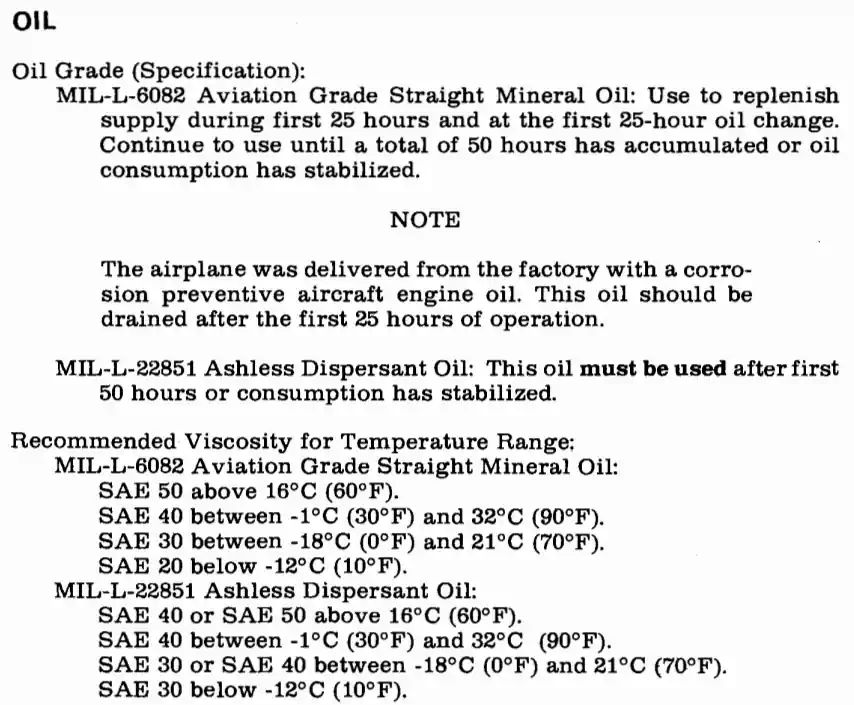

- The type of oil required may vary on numerous atmospheric and operation conditions, as stipulated by the aircraft operations manual [Figure 1]

- The AFM/POH or placards near the access panel provide information about the correct oil type and weight, as well as the minimum and maximum oil quantity

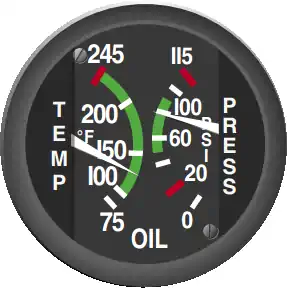

- System is monitored through pressure and temperature gauges [Figure 3]

- The loss of engine oil pressure would lead to engine vibrations, RPM would decrease, and the engine would eventually seize

- Viscosity: the ability of a liquid to resist flow

Heat Management:

- A critical purpose of engine oil is to help manage cooling

- This occurs by cool oil moving through warm areas, picking up the heat, and dissipating it through a radiator

Oil System Gauges:

-

Oil Pressure Gauge:

- The oil pressure gauge provides a direct indication of the oil system operation [Figure 3]

- It ensures the pressure in pounds per square inch (psi) of the oil supplied to the engine

- Green indicates the normal operating range, while red indicates the minimum and maximum pressures

- There should be an indication of oil pressure during engine start

- Refer to the AFM/POH for manufacturer limitations

-

Oil Temperature Gauge:

- The oil temperature gauge measures the temperature of oil [Figure 3]

- It is usually measured after passing through the oil cooler

- A green area shows the normal operating range and the red line indicates the maximum allowable temperature

- Unlike oil pressure, changes in oil temperature occur more slowly

- This is particularly noticeable after starting a cold engine, when it may take several minutes or longer for the gauge to show any increase in oil temperature

- Check oil temperature periodically during flight especially when operating in high or low ambient air temperature

- High oil temperature indications may signal:

- Plugged oil line or cooler

- low oil quantity (possible engine failure)

- Defective temperature gauge

- High oil temperatures can lead to metal on metal contact as viscosity decreases

- Low oil temperature indications may signal improper oil viscosity during cold weather operations

Oil/Lubrication Malfunctions/Emergencies:

- Oil consumption depends primarily upon the efficiency of the seals

- Oil can be lost through internal leakage, and, in some engines, by malfunctioning of the pressurizing or venting system

- Increases in oil temperature are not always associated with a drop in oil pressure, nor a rise in CHTs

-

Low Oil Pressure:

- Low oil pressure can be caused by an oil leak which leads to lack of oil in the system, or an ineffective oil pump

- These emergencies can be particularly detrimental when flying an aircraft utilizing a constant-speed propeller

-

Low Oil Pressure Primary Indications:

- Oil pressure will indicate low

-

Low Oil Pressure Secondary Indications:

- Rising Cylinder Head Temperatures (CHT)

- Oil temperature may rise (if the pressure drops rapidly then it is less likely you will have a corresponding temperature indication

- Rough engine indications

-

Low Oil Temperature:

Primary Indications:

- Oil temperature will indicate low

Secondary Indications:

-

High Oil Temperature:

-

High Oil Temperature Primary Indications:

- Oil temperature will indicate high

-

High Oil Temperature Secondary Indications:

- Other temperatures will indicate high

- Possible smoke

- Low oil pressure

- High RPM

-

High Oil Temperature Considerations:

- Open cowl flaps, if equipped

-

-

Oil Leaks:

- Oil on windscreen may come from engine or propeller

Oil System Inspections:

- Inspecting the oil system is not a routine check, but rather a detailed review of aircraft engine health

-

Oil Inspection:

- Pilots should inspect the oil as part of the pre-flight checklist

- Inspecting the oil is critical in determining the quantity and condition of oil

- Oil should never go below the Pilot Operating Handbook specified minimum quanty

- The color of the oil is a reflection of oil age and engine health

- New, clean oil should be light in color

- Dark oil is generally the result of contaminates and oxidation after many hours of operation

- Too dark is a judgement call based on the amount of hours of use

- Dark oil may be due to bad piston seals

- Larger oil sumps tend to absorb contaminents better as they hold more in suspension

- Smaller sumps should therefore be changed/drained more often

-

Oil Filter Inspection:

- It is never required, but pilots who own their airplane may elect to inspect the oil filter for tell-tale signs of wear

- Oil filters are designed to bypass, if clogged, but are only meant to last for the life of the oil

- Oil filters should be changed with every oil change

- Changing an oil filter often also allows for consistent engine health trend analysis

Private Pilot - Operation of Aircraft Systems Airman Certification Standards:

- To determine that the applicant exhibits satisfactory knowledge, risk management, and skills associated with the safe operation of systems on the airplane provided for the flight test

- References: FAA-H-8083-2, FAA-H-8083-3, FAA-H-8083-23, FAA-H-8083-25; POH/AFM

- Lesson Plan

Operation of Aircraft Systems Knowledge:

The applicant must demonstrate an understanding of:PA.I.G.K1:

Airplane systems, to include: (Note: If K1 is selected, the evaluator must assess the applicant's knowledge of at least three of the following sub-elements-

PA.I.G.K1a:

Primary flight controls -

PA.I.G.K1a:

Secondary flight controls -

PA.I.G.K1c:

Powerplant and propeller -

PA.I.G.K1d:

Landing gear -

PA.I.G.K1e:

Fuel, oil, and hydraulic -

PA.I.G.K1f:

Electrical -

PA.I.G.K1g:

Avionics -

PA.I.G.K1h:

Pitot-static, vacuum/pressure, and associated flight instruments -

PA.I.G.K1i:

Environmental -

PA.I.G.K1j:

Deicing and anti-icing -

PA.I.G.K1k:

Water Rudders -

PA.I.G.K1l:

Oxygen Systems

-

PA.I.G.K2:

Indications of and procedures for managing system abnormalities or failures

Operation of Aircraft Systems Risk Management:

The applicant demonstrates the ability to identify, assess, and mitigate risks, encompassing:PA.I.G.R1:

Failure to detect system malfunctions or failuresPA.I.G.R2:

Improper management of a system failurePA.I.G.R3:

Failure to monitor and manage automated systems

Operation of Aircraft Systems Skills:

The applicant demonstrates the ability to:PA.I.G.S1:

Operate at least three of the systems listed in K1a through K1l above appropriatelyPA.I.G.S2:

Use appropriate checklists properly

Private Pilot - Systems and Equipment Malfunctions Airman Certification Standards:

- To determine that the applicant exhibits satisfactory knowledge, risk management, and skills associated with system and equipment malfunctions appropriate to the airplane provided for the practical test and analyzing the situation and take appropriate action for simulated emergencies

- FAA-H-8083-2, FAA-H-8083-3; POH/AFM

Systems and Equipment Malfunctions Knowledge:

The applicant must demonstrate an understanding of:-

PA.IX.C.K1:

Partial or complete power loss related to the specific powerplant, including:-

PA.IX.C.K1a:

Engine roughness or overheat -

PA.IX.C.K1b: Carburetor or induction icing

-

PA.IX.C.K1c:

Loss of oil pressure -

PA.IX.C.K1d:

Fuel starvation

-

-

PA.IX.C.K2:

System and equipment malfunctions specific to the airplane, including:-

PA.IX.C.K2a:

Electrical malfunction -

PA.IX.C.K2b:

Vacuum/pressure and associated flight instrument malfunctions -

PA.IX.C.K2c:

Pitot/static system malfunction -

PA.IX.C.K2d:

Electronic flight deck display malfunction -

PA.IX.C.K2e:

Landing gear or flap malfunction -

PA.IX.C.K2f:

Inoperative trim

-

-

PA.IX.C.K3:

Smoke/fire/engine compartment fire -

PA.IX.C.K4:

Any other system specific to the airplane (e.g., supplemental oxygen, deicing) -

PA.IX.C.K5:

Inadvertent door or window opening

Systems and Equipment Malfunctions Risk Management:

The applicant demonstrates the ability to identify, assess, and mitigate risks, encompassing:-

PA.IX.C.R1:

Failure to use the proper checklist for a system or equipment malfunction -

PA.IX.C.R2:

Distractions, loss of situational awareness, or improper task management

Systems and Equipment Malfunctions Skills:

The applicant demonstrates the ability to:-

PA.IX.C.S1:

Describe appropriate action for simulated emergencies specified by the evaluator, from at least three of the elements or sub-elements listed in K1 through K5 above -

PA.IX.C.S2:

Complete the appropriate checklist

Conclusion:

- Oil systems reduce friction on moving parts, create better seals, reduce and remove heat, carry away contaminants and in some cases, run other systems

- Oil can be sent off for analysis which checks small particles not caught by filter, but a filter will hide big issues

- Many systems have pressurized sumps and a pressurized oil tank to ensure a constant head pressure to the lubrication pump to prevent pup cavitation at high altitudes

- Changing oil is permitted as preventative maintenance and provides an indication of engine health

- Oil consumption is relatively low in a gas turbine engine compared to a piston-type engine

- Still looking for something? Continue searching: