Oil/Lubrication System

Oil lubricates moving parts, cools the engine by reducing friction, and creates better seals, improves engine efficiency and longevity.

Aviation Oil/Lubrication System

Aviation Oil/Lubrication System Introduction

- Lubrication systems are responsible for lubrication, heat management, and collecting debris that result from operation of the powerplant/engine.

- Wet and Dry oil/lubrication systems keep aircraft well-oiled while maintaining proper operating temperature.

- Depending on the aircraft, oil also powers other systems and accessories.

- When you feel you have a solid understanding of aviation oil/lubrication systems, compare your knowledge against the oil/lubrication related airman certification standards.

- Once satisfied, close out with the topic summary and prepare for your next lesson.

Aviation Oil/Lubrication System

Oi/Lubrication System Design

- Lubrication systems consist of either a wet-sump or a dry-sump system.

- To differentiate between the two systems, think about what happens when the engine is off.

- Wet sump systems maintain oil in reservoirs/oil pans (sumps) integral to the engine while dry sumps do not, leaving the sump "dry."

-

Wet-Sump Oil/Lubrication Systems:

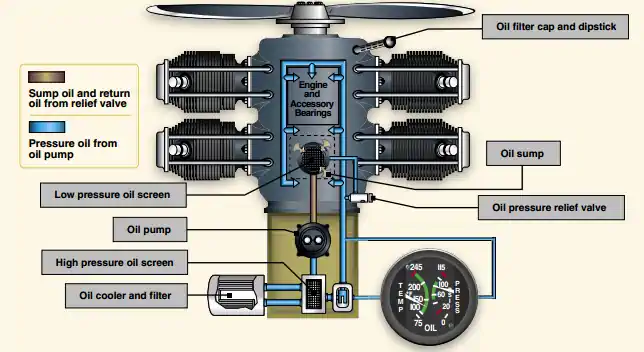

- In a wet-sump system, an integral reservoir stores oil. [Figure 1]

- The main component is the oil pump, which pumps oil from the sump and routes it to the engine.

- After the oil circulates throughout the engine, it returns to the sump.

- In some engines, additional lubrication occurs by the rotating crankshaft, which splashes oil (splash lubrication) onto various engine components.

-

Dry-Sump Oil/Lubrication Systems:

- Oil is contained in a separate tank and circulated through the engine by pumps.

- These tanks are always larger than the oil it is meant to contain to compensate for thermal expansion.

- An oil pump also supplies oil pressure in a dry-sump system, but the source of the oil is located externally to the engine in a separate oil tank.

- After oil circulates through the engine, it is pumped from the various locations in the engine back to the oil tank by scavenge pumps.

- Dry-sump systems allow for a greater volume of oil to be supplied to the engine, which makes them more suitable for very large reciprocating engines.

- Most jet engines will consist of a dry sump design.

- When checking the oil level on a dry-sump engine that has been sitting idle, readings may be inaccurate unless rotated (or "burped").

- Refer to your POH.

Aviation Oil/Lubrication System

Lubrication System Components

-

Oil Filter:

- The oil filter is responsible for screening the oil for foreign debris.

- Oil filters accomplish this by pushing oil through a one or more screens or paper filters.

-

Oil Screens:

- There are two types of oil screens:

- Pressure Screens, or;

- Suction Screens.

-

Suction Screens:

- Suction screens are screens placed before the oil pump in the lubrication system , filtering out the largest contaminents before they enter delicate system components.

-

Pressure Screens:

- Pressure screens filter finer particulates, down to 60 microns.

- There are two types of oil screens:

-

Paper Oil Filters:

- Paper oil filters are a newer technology in which paper completes the functions of an oil screen.

-

-

Oil Filler Cap/Dipstick:

- The oil filler cap/dipstick used to measure oil quantity is usually accessible through a panel in the engine cowling. [Figure 2]

- If the quantity does not meet the manufacturer's recommended operating levels, oil should be added.

- If oil is unexpectedly low, the source of oil burn/leak should be investigated.

-

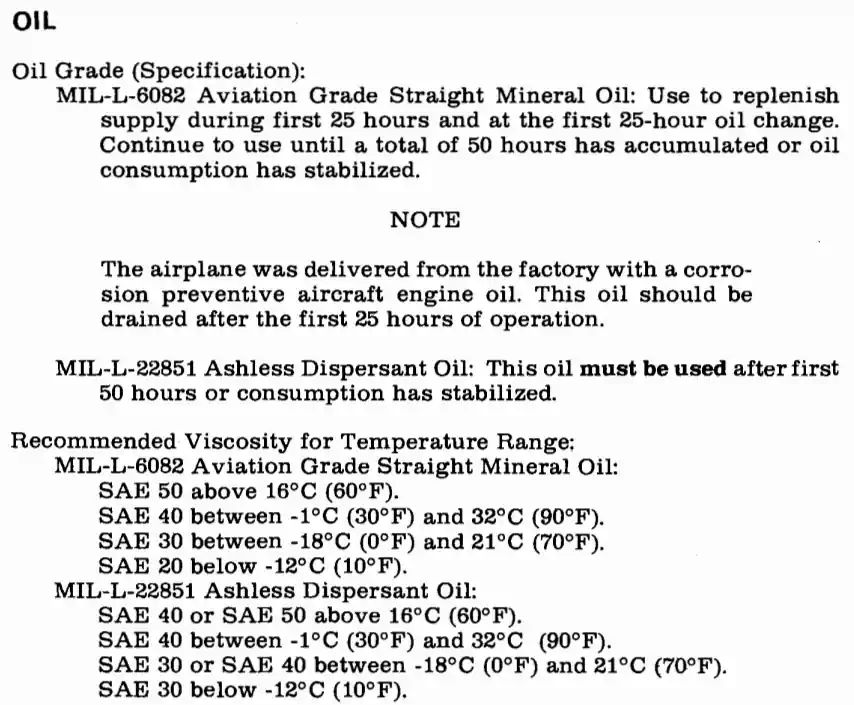

Oil:

- The type of oil required may vary on numerous atmospheric and operation conditions, as stipulated by the aircraft operations manual. [Figure 3]

- The AFM/POH or placards near the access panel provide information about the correct oil type and weight, as well as the minimum and maximum oil quantity.

- The loss of engine oil pressure would lead to engine vibrations, RPM would decrease, and the engine would eventually seize.

- Viscosity: the ability of a liquid to resist flow.

Aviation Oil/Lubrication System

Heat Management

- A critical purpose of engine oil is to help manage cooling.

- This occurs by cool oil moving through warm areas, picking up the heat, and dissipating it through a radiator.

Aviation Oil/Lubrication System

Oil System Gauges

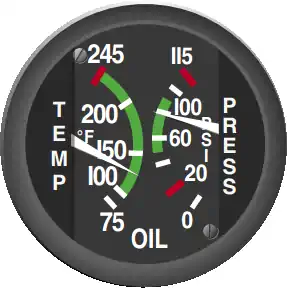

- System is monitored through pressure and temperature gauges [Figure 4]

-

Oil Pressure Gauge:

- The oil pressure gauge provides a direct indication of the oil system operation. [Figure 4]

- It ensures the pressure in pounds per square inch (psi) of the oil supplied to the engine.

- Green indicates the normal operating range, while red indicates the minimum and maximum pressures.

- There should be an indication of oil pressure during engine start.

- Refer to the AFM/POH for manufacturer limitations.

-

Oil Temperature Gauge:

- The oil temperature gauge measures the temperature of oil. [Figure 4]

- It is usually measured after passing through the oil cooler.

- A green area shows the normal operating range and the red line indicates the maximum allowable temperature.

- Unlike oil pressure, changes in oil temperature occur more slowly.

- This is particularly noticeable after starting a cold engine, when it may take several minutes or longer for the gauge to show any increase in oil temperature.

- Check oil temperature periodically during flight especially when operating in high or low ambient air temperature.

- High oil temperature indications may signal:

- Plugged oil line or cooler.

- low oil quantity (possible engine failure).

- Defective temperature gauge.

- High oil temperatures can lead to metal on metal contact as viscosity decreases.

- Low oil temperature indications may signal improper oil viscosity during cold weather operations.

Aviation Oil/Lubrication System

Oil/Lubrication Malunfctions/Emergencies

- Oil consumption depends primarily upon the efficiency of the seals.

- Oil can be lost through internal leakage, and, in some engines, by malfunctioning of the pressurizing or venting system.

- Increases in oil temperature are not always associated with a drop in oil pressure, nor a rise in CHTs.

-

Low Oil Pressure:

- Low oil pressure can be caused by an oil leak which leads to lack of oil in the system, or an ineffective oil pump.

- These emergencies can be particularly detrimental when flying an aircraft utilizing a constant-speed propeller.

-

Low Oil Pressure Primary Indications:

- Oil pressure will indicate low.

-

Low Oil Pressure Secondary Indications:

- Rising Cylinder Head Temperatures (CHT).

- Oil temperature may rise (if the pressure drops rapidly then it is less likely you will have a corresponding temperature indication.

- Rough engine indications.

-

Low Oil Temperature:

Primary Indications:

- Oil temperature will indicate low.

Secondary Indications:

-

High Oil Temperature:

-

High Oil Temperature Primary Indications:

- Oil temperature will indicate high.

-

High Oil Temperature Secondary Indications:

- Other temperatures will indicate high.

- Possible smoke.

- Low oil pressure.

- High RPM.

-

High Oil Temperature Considerations:

- Open cowl flaps, if equipped.

-

-

Oil Leaks:

- Oil on windscreen may come from engine or propeller.

Aviation Oil/Lubrication System

Oil System Inspections

- Inspecting the oil system is more than a routine check

- It is an opportunity for a detailed review of aircraft engine health.

-

Oil Inspection:

- Pilots should inspect the oil as part of the pre-flight checklist.

- Inspecting the oil is critical in determining the quantity and condition of oil.

- Oil should never go below the Pilot Operating Handbook specified minimum quanty.

- The color of the oil is a reflection of oil age and engine health.

- New, clean oil should be light in color.

- Dark oil is generally the result of contaminates and oxidation after many hours of operation.

- Too dark is a judgement call based on the amount of hours of use.

- Dark oil may be due to bad piston seals.

- Larger oil sumps tend to absorb contaminents better as they hold more in suspension.

- Smaller sumps should therefore be changed/drained more often.

- Note that while wet-sump systems can be checked by simply checking the dip stick before flight, a dry-sump system may require the engine be turned a few times to circulate residual oil in the engine back to the sump.

- This may be referred to as "burping."

-

Oil Filter Inspection:

- It is never required, but pilots who own their airplane may elect to inspect the oil filter for tell-tale signs of wear.

- Oil filters are designed to bypass, if clogged, but are only meant to last for the life of the oil.

- Oil filters should be changed with every oil change.

- Changing an oil filter often also allows for consistent engine health trend analysis.

Aviation Oil/Lubrication System

Aviation Oil/Lubrication System Conclusion

- Oil systems reduce friction on moving parts, create better seals, reduce and remove heat, carry away contaminants and in some cases, run other systems.

- Oil can be sent off for analysis which checks small particles not caught by filter, but a filter will hide big issues.

- Many systems have pressurized sumps and a pressurized oil tank to ensure a constant head pressure to the lubrication pump to prevent pup cavitation at high altitudes.

- Changing oil is permitted as preventative maintenance and provides an indication of engine health.

- Oil consumption is relatively low in a gas turbine engine compared to a piston-type engine.

- Still looking for something? Continue searching:

Aviation Oil/Lubrication System