Aircraft Electrical Systems

Electrical systems generate, regulate, and distribute electrical power throughout the aircraft for use in various systems.

Aircraft Electrical Systems Introduction

- The primary function of an aircraft electrical system is to generate, regulate, and distribute electrical power throughout the aircraft.

- Most aircraft are equipped with either a 14- or a 28-volt direct current electrical system.

- There are several different power sources on aircraft to power the aircraft electrical systems. These power sources include: engine-driven alternating current (AC) generators, auxiliary power units (APUs), and external power. The aircraft's electrical power system is used to operate the flight instruments, essential systems, such as anti-icing, and passenger services, such as cabin lighting

- Electricity is produced in two types depending on their use:

- Direct Current (DC): battery, generator, transformer-rectifier

- Alternating Current (AC): generator, inverter

- The electrical system is composed of numerous components which power various systems on the aircraft

Electrical Components

- Basic electrical systems consist of:

-

Alternator/Generator:

- Alternators and generators are engine-driven power source accessories which supply electric current to the aircraft's electrical system.

- Alternators and generators support in-flight operations while maintaining a sufficient electrical charge on the aircraft's battery.

- Aircraft electrical systems are generally designed around having either an alternator or a generator.

-

Alternators:

- Alternators rotate a magnetic field inside stationary coils of wires, producing alternating current

-

Alternator Advantages:

- Alternators produce sufficient current to operate the entire electrical system, even at slower engine speeds, by producing alternating current, which is converted (via a rectifier) to direct current.

- The electrical output of an alternator is more constant throughout a wide range of engine speeds.

- Alternators are more efficient, providing higher electrical output than generators at low RPMs

- Alternators are ligher and more comptact tha generators

- Alternators have fewer moving parts, requiring less maintenance and increasing reliability

-

Alternator Disadvantages:

- Require rectifier to produce DC power to the aircraft

-

Generators:

- In the generator, the conductors are copper wires that are wound around an armature that is bolted to the drive pulley, producing direct current

- As the armature rotates, the copper wires move through a magnetic field that is produced by permanent magnets which produces electrical power, a principle called electromagnetic induction

- Generators don't produce rated output until engine rpm is up in the midrange of operation - typically above 1,400 rpm

- Pilots who have experienced the rapid dimming of a landing light as they reduce engine rpm on short final will understand one of the drawbacks of a generator-powered system

-

Generator Advantages:

- Simplicity, producing DC power, not needing rectifying

- Not sensitive to errant electrical spikes or reversed polarity

- Produce electrical power even if the battery is dead

-

Generator Disadvantages:

- Heavy

- Lower electrical output

- Electrical noise and static that radiate to other avionics

- Require more maintenance than alternators

-

Multi-Engine (Dual) Systems:

- On a multiengine aircraft, each engine has an alternator or generator installed.

- Alternator or generator paralleling circuitry matches the output of each engine’s alternator/generator so that the electrical system load is shared equally between them.

- In the event of an alternator/generator failure, the inoperative unit can be isolated and the entire electrical system powered from the remaining one.

- Depending upon the electrical capacity of the alternator/generator, the pilot may need to reduce the electrical load (referred to as load shedding) when operating on a single unit.

- Learn more about alternator maintenance, read the AOPA's articles on caring for your alternator and 500-hour inspections

-

Battery:

- Electrical energy stored in a battery provides a source of electrical power for starting the engine and a limited supply of electrical power for use in the event the alternator or generator fails.

- Most direct-current generators will not produce a sufficient amount of electrical current at low engine RPM to operate the entire electrical system.

- During operations at low engine RPM, the electrical needs must be drawn from the battery, which can quickly be depleted.

- Trickle chargers (not a standard charger) may be beneficial to the battery life

- Some aircraft have two batteries, allowing for offsetting replacement times, but also bring extra connections, wire, etc. which adds complexity

-

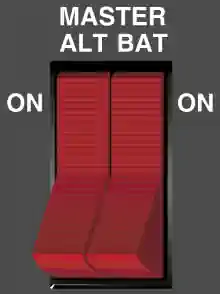

Master/Battery Switch:

-

Master Switch:

- The electrical system is turned on or off with a master switch.

- This would be the equivalent of turning your car keys to run electrical components without actually starting the car.

- Turning the master switch to the ON position provides electrical energy to all the electrical equipment circuits except the ignition system.

- For example, lights, radios, fuel gauges, Pitot heat, etc.

- The electrical system is turned on or off with a master switch.

-

Battery Switch:

- Many aircraft are equipped with a battery switch that controls the electrical power to the aircraft in a manner similar to the master switch.

-

-

Alternator/Generator Switch:

- An alternator switch is installed which permits the pilot to exclude the alternator from the electrical system in the event of alternator failure.

- With the alternator half of the switch in the OFF position, the entire electrical load is placed on the battery.

- All non-essential electrical equipment should be turned off to conserve battery power

-

External Power Unit Connections:

- Some aircraft have receptacles to which an external ground power unit (GPU) may be connected to provide electrical energy for starting which can be very useful, especially during cold weather starting

-

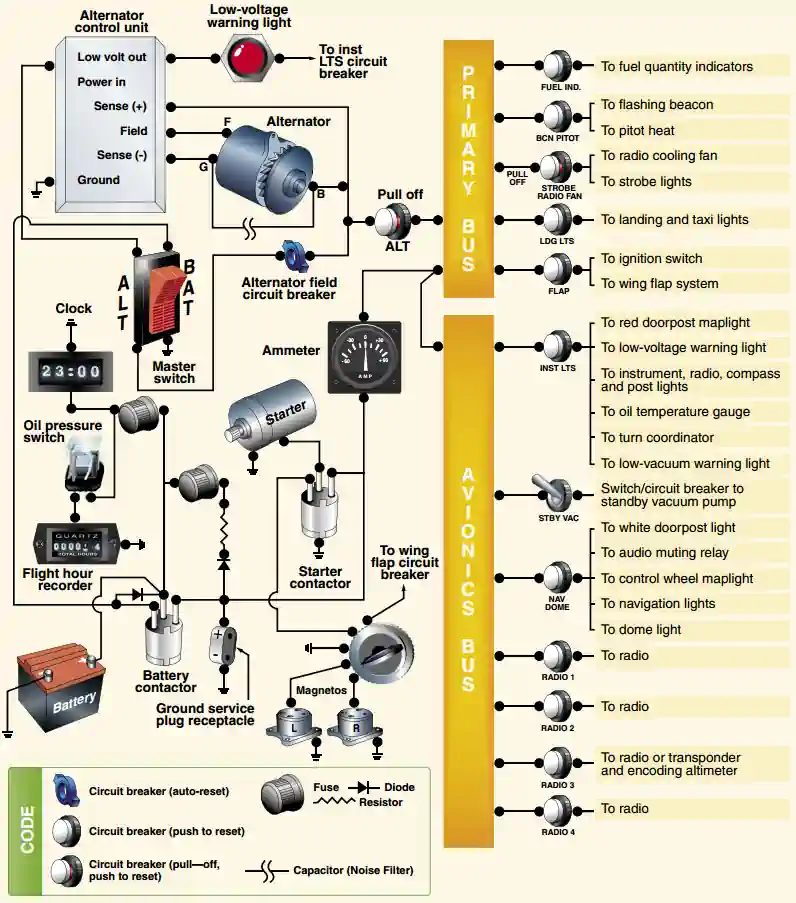

Bus Bar, Fuses, and Circuit Breakers:

- A bus bar is used as a terminal in the aircraft electrical system to connect the main electrical system to the equipment using electricity as a source of power.

- This simplifies the wiring system and provides a common point from which voltage can be distributed throughout the system.

- Fuses or circuit breakers are used in the electrical system to protect the circuits and equipment from electrical overload.

- Overloads can come from malfunctions, improper equipment or procedures, damaged or exposed wiring, lightning, etc.

- While these devices are carefully placed throughout the system, to the pilot they're usually installed in a consolidated location for ease of identification

- Spare fuses of the proper amperage limit should be carried in the aircraft to replace defective or blown fuses.

- Note that "one spare set of fuses, or three spare fuses of each kind required, that are accessible to the pilot in flight" are required if operating VFR at night per FAR 91.205.

- Circuit breakers have the same function as a fuse but can be manually reset, rather than replaced, if an overload condition occurs in the electrical system.

- Placards at the fuse or circuit breaker panel identify the circuit by name and show the amperage limit.

-

Voltage Regulator:

- For the electrical system to function properly, voltage must be steady and predictable throughout different engine power settings and electrical system loads, necessitating a device to regulate the system.

- A voltage regulator controls the rate of charge to the battery by stabilizing the generator or alternator electrical output.

- The generator/alternator voltage output should be higher than the battery voltage.

- For example, a 12-volt battery would be fed by a generator/alternator system of approximately 14 volts.

- The difference in voltage keeps the battery charged.

- Pilots can utilize aftermarket solutions as backups to panel gauges that can plug into cigarette lighters (if available) to provide voltage reetings. [Figure 3]

- Ensure the digital voltmeter matches the electrical system (i,e., 12V or 24V).

-

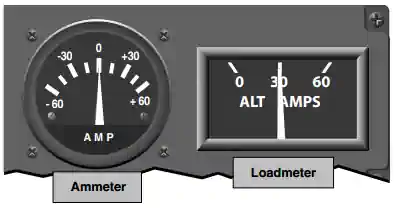

Ammeter/Loadmeter:

- The electrical load (or lack thereof) informs the pilot on the health of the aircraft's electrical system.

- By measuring the electrical system's amperage, the pilot can validate actual performance falls in line with the desired performance.

- The electrical load demanded by an aircraft's electrical system is measured with the use of an ammeter or loadmeter.

-

Ammeter:

- Ammeters are designed with the zero point in the center of the face and a negative or positive indication on either side. [Figure 4]

- An ammeter is used to monitor the performance of the aircraft electrical system which shows if the alternator/generator is producing an adequate supply of electrical power.

- It also indicates whether or not the battery is receiving an electrical charge.

- When the pointer of the ammeter is on the plus side, it shows the charging rate of the battery.

- A minus indication means more current is being drawn from the battery than is being replaced.

- A full-scale deflection indicates a malfunction

- A full-scale minus deflection indicates a malfunction of the alternator/generator.

- A full-scale positive deflection indicates a malfunction of the regulator.

- In either case, consult the AFM or POH for appropriate action to be taken.

- Not all aircraft are equipped with an ammeter-some have a warning light that, when lighted, indicates a discharge in the system as a generator/alternator malfunction

- Refer to the AFM or POH for appropriate action to be taken

-

Loadmeter:

- The loadmeter reflects the total percentage of the load placed on the generating capacity of the electrical system by the electrical accessories and battery [Figure 4]

- When all electrical components are turned off, it reflects only the amount of charging current demanded by the battery

-

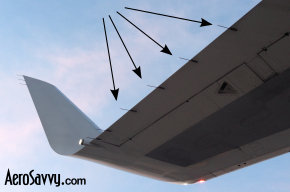

Static Wicks/Dischargers:

- Aircraft buildup static electricity via the friction generated by traveling through the air.

- Dry air in particular helps insulate electricity discharge making their presence even more useful in winter.

- Static wicks/dischargers enable the controlled electrical discharge back into the atmosphere, isolating electrical noise and preventing it from interfering with aircraft navigation and communication equipment.

- These wicks/discharges are not much more than exposed metal, grounded to the aircraft, and mounted to the trailing edge of an aircraft surface like the wing

- Additionally it is necessary to dissipate static buildup during refueling to prevent a spark and therefore ignition of fuel vapors.

- Static wicks/dischargers also provide additional lightning protection as strikes will often use static wicks/dischargers as the path of lease resistance to flow out of an aircraft when struck.

- Learn more about static wicks/dischargers on the AOPA's "How It Works: Static Wicks."

- Aircraft buildup static electricity via the friction generated by traveling through the air.

-

Associated Wiring:

- This type of gauge has a scale beginning with zero and shows the load being placed on the alternator/generator

Electrical Equipment

- Equipment that commonly use the electrical system include:

- Aircraft Lights

- Radio Equipment

- Turn Indicator

- Fuel Gauges

- Electric Fuel Pump

- Stall Warning System

- Pitot Heat

- Starting Motor

Common Training Aircraft Electrical System Characteristics

-

Cessna-172:

- 28 Volt DC electrical system

- Powered by 60-amp alternator (belt-driven) and a 24-volt battery (left forward side of firewall)

- Power distribution module (J-box) located on the left forward side of the firewall houses all relays, the alternator control unit, and the external power connector within the module

-

Piper Arrow:

- 14 Volt DC electrical System

- Powered by a 60-amp alternator (belt-driven) and a 12-volt, 35 ampere hour battery

Electrical Errors and Malfunctions

-

Alternator Failure:

- Leading to failure, alternators may cause a whining sound to be picked up on the headset as well as generally under-perform (degraded charging)

- An alternator failure can be recognized by the batteries picking up the electrical load on the aircraft

- The aircraft will continue to fly without the alternator, if that is the only issue

- However, aircraft components such as radios and lights will eventually cease to function

- This means the aircraft will not be legal to fly and may prohibit safe landing at the intended airport due to the loss of radios and transponder

-

Alternator Failure Considerations:

- Alternator failures at night should be considered an emergency in most situations

- Declaring emergency to buys attention and priority handling

- How much battery time you have depends on the health and size of your battery, as well as how quickly you notice and respond to the failure

- Turn off as much as you reasonably can

- Consider turning off nonessential lights, especially non-LED lights

- Pitot heat uses a lot of power, but don't turn it off if you need it

- You can likely turn off one radio, and possibly your transponder if you're not being vectored by ATC

- If you have an iPad you can navigate with, turn off the GPS too

- Keep radio transmissions to a minimum-they're a significant power draw-and consider using a handheld radio proactively

- Turn off autopilots

- Dim the backlighting on glass displays as low as possible. If you have instruments with internal battery backups, understand how to make them switch to their internal batteries if not automatic

- If you need more range than the battery alone will provide, you still have an option:

- Turn off the master switch and fly by iPad or dead reckoning until you're in range of an airport

- Then turn the master back on and you'll have power to spare when you need it most

- This is even an option in IMC on an IFR flight plan

- Let ATC know when and where you plan to turn your radios back on, and they'll provide a frequency to call, and the controllers there will be expecting you

- Save battery for approach phase, including instrument approaches, pilot-controlled lighting, as well as for electric flaps and landing gear

- Tell ATC your plan and ETA before the battery dies so they can look, provide signals, and clear airspace

- Alternator failures at night should be considered an emergency in most situations

-

Low Battery Voltage:

- Insufficient voltage from dead bat may effect an alternator, but especially a generator's ability to charge

Private Pilot (Airplane) Operation of Aircraft Systems Airman Certification Standards

- Objective: To determine whether the applicant exhibits satisfactory knowledge, risk management, and skills associated with safe operation of systems on the airplane provided for the flight test.

- References: FAA-H-8083-2 (Risk Management Handbook), FAA-H-8083-3 (Airplane Flying Handbook), FAA-H-8083-23 (Seaplane, Skiplane, and Float/Ski Equipped Helicopter Operations Handbook), FAA-H-8083-25 (Pilot Handbook of Aeronautical Knowledge); POH/AFM

- Note: If K1 is selected, the evaluator must assess the applicant's knowledge of at least three sub-elements

- Private Pilot Operation of Aircraft Systems Lesson Plan

Private Pilot (Airplane) Operation of Aircraft Systems Knowledge:

The applicant demonstrates an understanding of:-

PA.I.G.K1:

Airplane systems, including:-

PA.I.G.K1a:

Primary flight controls. -

PA.I.G.K1a:

Secondary flight controls. -

PA.I.G.K1c:

Powerplant and propeller. -

PA.I.G.K1d:

Landing gear. -

PA.I.G.K1e:

Fuel, oil, and hydraulic. -

PA.I.G.K1f:

Electrical. -

PA.I.G.K1g:

Avionics. -

PA.I.G.K1h:

Pitot-static, vacuum/pressure, and associated flight instruments. -

PA.I.G.K1i:

Environmental. -

PA.I.G.K1j:

Deicing and anti-icing. -

PA.I.G.K1k:

Water Rudders (ASES, AMES). -

PA.I.G.K1l:

Oxygen Systems.

-

-

PA.I.G.K2:

Indications of and procedures for managing system abnormalities or failures.

Private Pilot (Airplane) Operation of Aircraft Systems Risk Management:

The applicant is able to identify, assess, and mitigate risks associated with:-

PA.I.G.R1:

Detection of system malfunctions or failures. -

PA.I.G.R2:

Management of a system failure. -

PA.I.G.R3:

Monitoring and management of automated systems.

Private Pilot (Airplane) Operation of Aircraft Systems Skills:

The applicant exhibits the skills to:-

PA.I.G.S1:

Operate at least three of the systems listed in K1a through K1l appropriately. -

PA.I.G.S2:

Complete the appropriate checklist(s).

Private Pilot (Airplane) Systems and Equipment Malfunctions Airman Certification Standards

- Objective: To determine whether the applicant exhibits satisfactory knowledge, risk management, and skills associated with system and equipment malfunctions appropriate to the airplane provided for the practical test

- References: FAA-H-8083-2 (Risk Management Handbook), FAA-H-8083-3 (Airplane Flying Handbook), FAA-H-8083-25 (Pilot Handbook of Aeronautical Knowledge); POH/AFM

- Private Pilot (Airplane) Systems and Equipment Malfunctions Lesson Plan.

Private Pilot (Airplane) Systems and Equipment Malfunctions Knowledge:

The applicant demonstrates an understanding of:-

PA.IX.C.K1:

Causes of partial or complete power loss related to the specific type of powerplant(s).-

PA.IX.C.K1a:

[Archived]. -

PA.IX.C.K1b:

[Archived]. -

PA.IX.C.K1c:

[Archived]. -

PA.IX.C.K1d:

[Archived].

-

-

PA.IX.C.K2:

System and equipment malfunctions specific to the aircraft, including:-

PA.IX.C.K2a:

Electrical malfunction. -

PA.IX.C.K2b:

Vacuum/pressure and associated flight instrument malfunctions. -

PA.IX.C.K2c:

Pitot/static system malfunction. -

PA.IX.C.K2d:

Electronic flight deck display malfunction. -

PA.IX.C.K2e:

Landing gear or flap malfunction. -

PA.IX.C.K2f:

Inoperative trim.

-

-

PA.IX.C.K3:

Causes and remedies for smoke or fire onboard the aircraft. -

PA.IX.C.K4:

Any other system specific to the airplane (e.g., supplemental oxygen, deicing). -

PA.IX.C.K5:

Inadvertent door or window opening.

Private Pilot (Airplane) Systems and Equipment Malfunctions Risk Management:

The applicant is able to identify, assess, and mitigate risks associated with:-

PA.IX.C.R1:

Checklist usage for a system or equipment malfunction. -

PA.IX.C.R2:

Distractions, task prioritization, loss of situational awareness, or disorientation. -

PA.IX.C.R3:

Undesired aircraft state. -

PA.IX.C.R4:

Startle response.

Private Pilot (Airplane) Systems and Equipment Malfunctions Skills:

The applicant exhibits the skills to:-

PA.IX.C.S1:

Describe appropriate action for simulated emergencies specified by the evaluator, from at least three of the elements or sub-elements listed in K1 through K5 above. -

PA.IX.C.S2:

Complete the appropriate checklist(s).

Aircraft Electrical Systems Conclusion

- Although not part of what is considered the traditional electrical system, magnetos are a related electrical system element, self-contained to provide the engine all of the electrical power it needs to continue operating safely

- If you do not already have one, consider purchasing a hand held radio

- Still looking for something? Continue searching: