Aviation Fuel Systems

The fuel system provides an uninterrupted flow of clean fuel from the tanks to the aircraft's powerplant.

Introduction

Introduction

- Aviation fuel systems require the delivery of uninterrupted fuel to the engine under all conditions of engine power, altitude, attitude, and during all flight maneuvers.

- Various components, controls, and indicators provide engines with the uninterrupted aviation fuel necessary for the powerplant to operate.

- Refueling operations are careful to mitigate hazards, such as fuel contaminates

- To get started, you may wish to review common training aircraft fuel system characteristics.

- Pilots must be familiar with potential anomalies and malfunctions that may occur and how to manage them.

Aviation Fuel Systems

Aviation Fuel Systems

- Two common classifications apply to fuel systems in small aircraft:

-

Gravity-Feed System:

- The gravity-feed system utilizes the force of gravity to transfer the fuel from the tanks to the engine. [Figure 1]

- For example, on high-wing airplanes, the fuel tanks are installed in the wings, and the fuel flows down (gravity) through the system and into the carburetor.

- Gravity-fed systems reduce or eliminate the need for fuel pumps, simplifying aviation fuel systems.

- The gravity-feed system utilizes the force of gravity to transfer the fuel from the tanks to the engine. [Figure 1]

-

Fuel-Pump System:

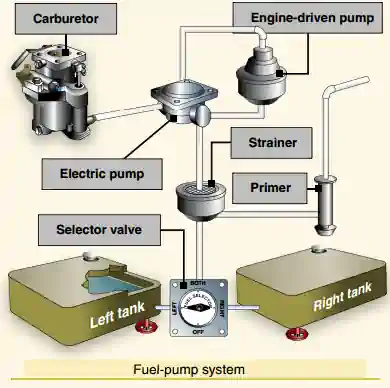

- If the design of the aircraft is such that gravity cannot be used to transfer fuel, fuel pumps are installed. [Figure 2]

- For example, on low-wing airplanes, the fuel tanks in the wings are located below the carburetor, requiring a pump.

- Aircraft with fuel pump systems have two fuel pumps.

- The main pump system is engine-driven, with an electrically driven auxiliary pump provided for use at the engine start and if the engine pump fails.

- The auxiliary pump, also known as a boost pump, provides added reliability to the fuel system and is electrically driven by a switch in the flight deck.

- If the design of the aircraft is such that gravity cannot be used to transfer fuel, fuel pumps are installed. [Figure 2]

-

Volatility & Flash Point:

- Volatility: a fuel's tendency to vaporize

- A more highly volatile fuel will vaporize at lower temperatures than fuel with a lower volatility rating.

- An increase in temperature increases volatility, forming more vapors.

- When enough vapors form, fuel will ignite readily, which is the flash point.

- Flash Point: the lowest temperature at which a combustible liquid (fuel) gives off vapors in sufficient quantity to ignite with the application of flame.

- Volatility: a fuel's tendency to vaporize

Fuel System Design

Fuel System Design

- The fuel system consists of components, controls, and indicators.

-

Fuel System Components:

-

Fuel Tanks:

- The fuel tanks are normally located inside the wings of an airplane.

- Tanks vary in construction by aircraft but generally use a "wet-wing," or flexible bladders:

- A wet-wing is an integral fuel tank where the wing structure is sealed and used as the fuel tank.

- A flexible bladder is a rubber tank mounted inside the wing's frame.

- Tanks will have a filler opening on top of the wing through which they can be filled.

- The tanks are vented to the outside to maintain atmospheric pressure inside the tank through the filler cap or a tube extending through the wing's surface.

- Fuel tanks also include an overflow drain that may stand alone or be collocated with the fuel tank vent.

- Vents allow fuel to expand as temperature increases without damaging the tank itself.

- If filling the tanks on a hot day, it is not unusual to see fuel coming from the overflow drain.

- Fuel/oil coolers exchange hot oil against cold fuel for cooler oil against warmer fuel.

-

Fuel Strainers, Sumps, and Drains:

- After leaving the fuel tank and before it enters the carburetor, the fuel passes through a Fuel Strainer [Amazon], which removes any moisture and other sediments in the system.

- Since these contaminants are heavier than aviation fuel, they settle in a sump at the bottom of the strainer assembly.

- A sump is a low point in a fuel system and/or fuel tank.

- Fuel samples should be drained and checked visually for water and contaminants.

- Water in the sump is hazardous because, in cold weather, the water can freeze and block fuel lines.

- In warm weather, it can flow into the carburetor and stop the engine.

- If water is present in the sump, more water in the fuel tanks is probable, and they should be drained until there is no evidence of water.

- Never take off until all water and contaminants have been removed from the engine fuel system.

- Because of the variation in fuel systems, become thoroughly familiar with the systems that apply to the aircraft being flown.

- Consult the AFM/POH for specific operating procedures.

-

-

Fuel System Controls:

-

Fuel Primer:

- Both gravity-feed and fuel-pump systems may incorporate a fuel primer into the system.

- The fuel primer draws fuel from the tanks to vaporize fuel directly into the cylinders before starting the engine.

- During cold weather, when engines are difficult to start, the fuel primer helps because there is not enough heat to vaporize the fuel in the carburetor.

- It is important to lock the primer in place when it is not in use.

- If the knob is free to move, it may vibrate out during flight and can cause an excessively rich mixture.

- To avoid over-priming, read the priming instructions for the aircraft.

- Failure to prime correctly can result in engine fires.

-

Fuel Selectors:

- The fuel selector valve allows the selection of fuel from various tanks. [Figure 4]

- A common type of selector valve contains four positions:

- LEFT: Selecting the LEFT position allows fuel to be fed only from that tank.

- RIGHT: Selecting the RIGHT position allows fuel to be fed only from that tank.

- BOTH: Selecting the BOTH position allows fuel to be fed from both tanks simultaneously.

- OFF: selecting the OFF position cuts fuel to the engine.

- Varying the position may be used to balance the amount of fuel remaining in each wing tank.

- Fuel placards show limitations on fuel tank usage, such as "level flight only" and/or "both" for landings and takeoffs.

- Pilots must remember to switch tanks if not on "BOTH."

- Buying a watch [Amazon] (or other device [Amazon]) with an alarm might help

-

Fuel Crossfeed:

- Fuel crossfeed systems are also unique to multiengine airplanes.

- Using crossfeed, an engine can draw fuel from a fuel tank located in the opposite wing.

- On most multiengine airplanes, operation in the crossfeed mode is an emergency procedure used to extend airplane range and endurance in OEI flight.

- There are a few models that permit crossfeed as a normal, fuel balancing technique in normal operation, but these are not common.

- The AFM/POH describes crossfeed limitations and procedures that vary significantly among multiengine airplanes.

- Manufacturers may or may not require a crossfeed check before every flight.

- Crossfeed lines are ideal places for water and debris to accumulate unless they are used from time to time and drained using their external drains during preflight.

- Crossfeed is ordinarily not used for completing a flight with one engine inoperative when an alternate airport is nearby.

- Pilots should never use crossfeed during takeoff or for normal landing operations with both engines operating.

- A landing with one engine inoperative using crossfeed may be necessary if setting normal fuel flow would cause the operative engine to fail.

- Checking crossfeed operation on the ground with a quick repositioning of the fuel selectors does nothing more than ensure freedom of motion of the handle.

- To actually check crossfeed operation, a complete, functional crossfeed system check should be accomplished.

- To do this, each engine should be operated from its crossfeed position during the run-up.

- The engines should be checked individually and allowed to run at moderate power (1,500 rpm minimum) for at least 1 minute to ensure that fuel flow can be established from the crossfeed source.

- Upon completion of the check, each engine should be operated for at least 1 minute at moderate power from the main (takeoff) fuel tanks to reconfirm fuel flow prior to takeoff.

- Fuel crossfeed systems are also unique to multiengine airplanes.

-

-

Fuel System Indicators:

-

Fuel Quantity Gauges:

- The fuel quantity gauges display the amount measured (gallons or pounds) by a sensing unit in each fuel tank.

- Gauge performance is governed by FAR 23.2430.

- While FAR language mentions, "each fuel quantity indicator must be calibrated to read "zero" during level flight when the quantity of fuel remaining in the tank is equal to the unusable fuel supply," their accuracy (not calibration) is required to be accurate at any level to meet FAR 91.205.

- The takeaway is to not rely solely on the accuracy of the fuel quantity gauges.

-

Fuel Flow Gauges:

- Fuel flow gauges indicate the amount of fuel flowing through the system.

-

Fuel Pressure Gauges:

- If a fuel pump is installed in the fuel system, a fuel pressure gauge is also included.

- This gauge indicates the pressure in the fuel lines.

- The normal operating pressure can be found in the AFM/POH or on the gauge by color-coding.

-

Aviation Fuel Grades

Aviation Fuel Grades

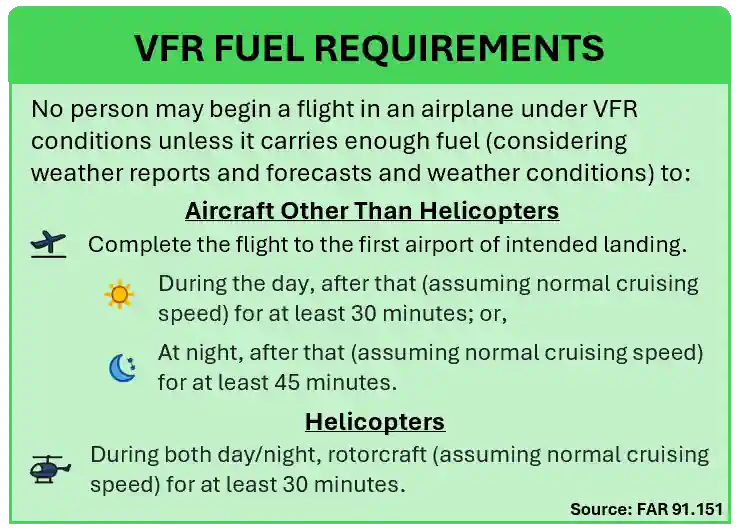

- Aviation gasoline (AVGAS) is identified by an octane or performance number (grade), which designates the antiknock value or knock resistance of the fuel mixture in the engine cylinder. [Figure 4]

- The higher the grade of gasoline, the more pressure the fuel can withstand without detonating.

- Lower fuel grades are used in lower-compression engines because these fuels ignite at a lower temperature.

- Higher fuel grades are used in higher-compression engines because they ignite at higher temperatures but not prematurely.

- The proper fuel grade is stated in the AFM/POH, on placards in the flight deck, and next to the filler caps.

- Care must be exercised to ensure that the correct aviation grade is being used for the specific type of engine.

- If the proper fuel grade is not available, use the next higher (never the lower!) grade as a substitute.

- This can cause the cylinder head temperature and engine oil temperature to exceed their normal operating ranges, which may result in detonation.

- Automotive gas should NEVER be used in aircraft engines unless the aircraft has been modified with a Supplemental Type Certificate (STC) issued by the Federal Aviation Administration (FAA).

- Exercise care to ensure the correct aviation grade for the specific engine type.

- Aircraft with reciprocating engines by the octane, performance number, and the AVGAS abbreviation.

- Although AVGAS 100LL performs the same as grade 100, the "LL" indicates low lead content.

- Fuel for aircraft with turbine engines is classified as JET A, JET A-1, and JET B.

- Jet fuel is basically kerosene and has a distinctive kerosene smell.

- Since the use of the correct fuel is critical, dyes are added to help identify the type and grade of fuel.

- In addition to the color of the fuel itself, the color-coding system extends to decals and various airport fuel handling equipment.

- All AVGAS is identified by name, using white letters on a red background.

- White letters on a black background identify turbine fuels.

-

100VLL AVGAS:

- Special Airworthiness Information Bulleting (SAIB) NE-11-15 advises that grade 100VLL AVGAS is acceptable for use on aircraft and engines.

- 100VLL meets all performance requirements of grades 80, 91, 100, and 100LL; meets the approved operating limitations for aircraft and engines certificated to operate with these other grades of AVGAS; and is basically identical to 100LL AVGAS.

- The lead content of 100VLL is reduced by about 19 percent.

- 100VLL is blue like 100LL and virtually indistinguishable.

-

Sustainable Aviation Fuel:

- Several agencies across the world have contributed to the development of sustainable aviation fuel.

- SAF is intended to replace 100LL, removing lead entirely while creating sustainable sources of aviation-quality fuel.

- While SAF is available in many locations, pilots are urged to check if it is compatible with their engine before using it.

Refueling Procedures

Refueling Procedures

- The hazards posed by static electricity during refueling require mitigation before fueling operations can begin:

- Static electricity forms by the friction of air passing over the surfaces of an aircraft in flight and by fuel flow through the hose and nozzle during refueling.

- Nylon, Dacron, or wool clothing is especially prone to accumulate and discharge static electricity from the person to the funnel or nozzle.

- To guard against the possibility of static electricity igniting fuel fumes, a ground wire should be attached to the aircraft before the fuel cap is removed from the tank.

- Pull the grounding cable from the refueling station to a length that locks, and then attach to an unpainted piece of the aircraft.

- To rewind, pull until the slack releases and walk it into the refueling station.

- Because both the aircraft and refueler have different static charges, bonding both components to each other is critical.

- This means by contacting metal to metal, the static differential charge is equalized.

- The refueling nozzle should be bonded to the aircraft before refueling begins and should remain bonded throughout the refueling process.

- When a fuel truck is used, it should be grounded before the fuel nozzle contacting the aircraft.

- If fueling from drums or cans is necessary, proper bonding and grounding connections are important.

- Drums should be placed near grounding posts and the following sequence of connections observed:

- Drum to ground.

- Ground to aircraft.

- Bond drum to aircraft or nozzle to aircraft before the fuel cap is removed.

- When disconnecting, reverse the order.

- The passage of fuel through a chamois increases the charge of static electricity and the danger of sparks.

- The aircraft must be properly grounded and the nozzle, chamois filter, and funnel bonded to the aircraft.

- If a can is used, it should be connected to either the grounding post or the funnel.

- Under no circumstances should a plastic bucket or similar non-conductive container be used in this operation.

- Some sort of eye protection should be worn and refueling performed in a well-ventilated area to avoid bodily harm

- See also: Technique: D.I.Y. Fueling

-

Static Electricity Mitigation:

- Static electricity is formed by the friction of air passing over the surfaces of an aircraft in flight and by the flow of fuel through the hose and nozzle during refueling.

- Static electricity discharge poses a safety risk when refueling, resulting in the installation of static wicks/dischargers and use of grounding wires when refueling.

- Grounding cable should be attached to an unpainted, non-corroded surface of the airplane.

- If not specified by the manufacturer, the exhaust stack or tie downs may serve this purpose well.

- Ground yourself as well by holding the wire with bare hands to avoid being a static course.

- Even the fuel nozzle can carry static electricity - keep it in contact with the metal inside the fuel port to maintain it's ground as well.

Fuel Contamination

Fuel Contamination

- Accidents attributed to powerplant failure from fuel contamination have often been traced to:

- Inadequate preflight inspection by the pilot

- Servicing aircraft with improperly filtered/mixed fuel from small tanks or drums

- Storing aircraft with partially filled fuel tanks

- Lack of proper maintenance

- Types of contaminate:

- Chemical: usually resulting from inadvertent mixing of petroleum products, this type affects the chemical and physical properties of the fuel and can only be detected by specific laboratory tests.

- Material (particulate): generally consists of water, microbiological growth, and particulate matter which can usually be detected visually.

- Microbiological: consists of living organisms that grow at the fuel-water interface.

- Fuel should be drained from the fuel strainer quick drain and from each fuel tank sump into a transparent container, and then checked for dirt and water.

- Dirt should be easy to see floating in the sample but water, since it is more dense, will sink to the bottom.

- Water will be clear against the AVGAS color you are using.

- The mixing of different fuel types may not be apparent by look or smell, but should be considered.

- When the fuel strainer is being drained, water in the tank may not appear until all the fuel has been drained from the lines leading to the tank.

- This indicates that water remains in the tank, and is not forcing the fuel out of the fuel lines leading to the fuel strainer.

- Therefore, drain enough fuel from the fuel strainer to be certain that fuel is being drained from the tank.

- The amount will depend on the length of fuel line from the tank to the drain.

- If water or other contaminants are found in the first sample, drain further samples until no trace appears.

- Water may also remain in the fuel tanks after the drainage from the fuel strainer has ceased to show any trace of water.

- This residual water can be removed only by draining the fuel tank sump drains.

- Water is the principal fuel contaminant.

- Suspended water droplets in the fuel can be identified by a cloudy appearance of the fuel, or by the clear separation of water from the colored fuel, which occurs after the water has settled to the bottom of the tank.

- As a safety measure, the fuel sumps should be drained before every flight during the preflight inspection.

- Fuel tanks should be filled after each flight or after the last flight of the day to prevent moisture condensation within the tank.!-- PHAK [2023] (Chapter 7) Fuel Systems -->

- To prevent fuel contamination, avoid refueling from cans and drums.

- In remote areas or in emergency situations, there may be no alternative to refueling from sources with inadequate anti-contamination systems.

- While a chamois skin and funnel may be the only possible means of filtering fuel, using them is hazardous.

- Remember, the use of a chamois will not always ensure decontaminated fuel.

- Worn-out chamois will not filter water; neither will a new, clean chamois that is already water-wet or damp.

- Most imitation chamois skins will not filter water.

- Color Identification:

- Note that water and/or Jet A fuel mixed with the common 100LL will still appear blue, albeit not as blue.

- However, unlike Jet A, which will remain mixed, water will separate from fuel.

- Smell:

- Jet A Smells like kerosene.

- Touch:

- Pour fuel on a white paper towel.

- If the fuel evaporates quickly, leaves a slight blue tint, and is dry to the touch, those are good signs that it's 100LL.

- If jet fuel is present, it will leave an oily sheen and it won't evaporate quickly.

- Gascolators may be used to internally filter water and debris prior to fuel routing to the engine for combustion.

Fuel System Icing

Fuel System Icing

- Ice formation in the aircraft fuel system results from the presence of water in the fuel system.

- This water may be undissolved or dissolved. One condition of undissolved water is entrained water that consists of minute water particles suspended in the fuel.

- This may occur as a result of mechanical agitation of free water or conversion of dissolved water through temperature reduction.

- Entrained water settles out in time under static conditions and may or may not be drained during normal servicing, depending on the rate at which it is converted to free water.

- In general, it is not likely that all entrained water can ever be separated from fuel under field conditions.

- The settling rate depends on a series of factors including temperature, quiescence, and droplet size.

- The droplet size varies depending upon the mechanics of formation.

- Usually, the particles are so small as to be invisible to the naked eye, but in extreme cases, can cause slight haziness in the fuel.

- Water in solution cannot be removed except by dehydration or by converting it through temperature reduction to entrained, then to free water.

- Another condition of undissolved water is free water that may be introduced as a result of refueling or the settling of entrained water that collects at the bottom of a fuel tank.

- Free water is usually present in easily detected quantities at the bottom of the tank, separated by a continuous interface from the fuel above.

- Free water can be drained from a fuel tank through the sump drains, which are provided for that purpose.

- Free water, frozen on the bottom of reservoirs, such as the fuel tanks and fuel filter, may render water drains useless and can later melt releasing the water into the system thereby causing engine malfunction or stoppage.

- If such a condition is detected, the aircraft may be placed in a warm hangar to reestablish proper draining of these reservoirs, and all sumps and drains should be activated and checked prior to flight.

- Entrained water (i.e., water in solution with petroleum fuels) constitutes a relatively small part of the total potential water in a particular system, the quantity dissolved being dependent on fuel temperature and the existing pressure and the water volubility characteristics of the fuel.

- Entrained water freezes in mid fuel and tends to stay in suspension longer since the specific gravity of ice is approximately the same as that of AVGAS.

- Water in suspension may freeze and form ice crystals of sufficient size such that fuel screens, strainers, and filters may be blocked.

- Some of this water may be cooled further as the fuel enters carburetor air passages and causes carburetor metering component icing, when conditions are not otherwise conducive to this form of icing.

-

Fuel System Icing Prevention Procedures:

- The use of anti-icing additives for some aircraft has been approved as a means of preventing problems with water and ice in AVGAS.

- Some laboratory and flight testing indicates that the use of hexylene glycol, certain methanol derivatives, and ethylene glycol mononethyl ether (EGME) in small concentrations inhibit fuel system icing.

- These tests indicate that the use of EGME at a maximum 0.15 percent by volume concentration substantially inhibits fuel system icing under most operating conditions.

- The concentration of additives in the fuel is critical.

- Marked deterioration in additive effectiveness may result from too little or too much additive.

- Pilots should recognize that anti-icing additives are in no way a substitute or replacement for carburetor heat.

- Aircraft operating instructions involving the use of carburetor heat should be adhered to at all times when operating under atmospheric conditions conducive to icing.

Aviation Fuel Anomalies & Malfunctions

Aviation Fuel System Anomalies & Malfunctions

-

Fuel Imbalance:

- Many aircraft are equipped with a fuel selector that allows you to select which tank, or both, to draw fuel.

- Aircraft can, at times, develop a fuel imbalance from various sources:

- Prolonged turns in the same direction

- Mechanical reasons

- Improper monitoring of the fuel selector valve.

- If a fuel imbalance occurs, select the appropriate (fullest tank) to even out the fuel levels.

-

System Failures:

- Running a tank completely dry may allow air to enter the fuel system and cause a vapor lock, which makes it difficult to restart the engine.

- The fuel becomes so hot on fuel-injected engines that it can vaporize in the fuel line, not allowing fuel to reach the cylinders.

-

Loss of Fuel Pressure:

- Loss of fuel pressure can be caused by malfunctioning/failed pumps or cavitation.

-

Fuel Leaks:

- Fuel leave severity will dictate the response required.

- Aside from running out of gas (a common accident causal factor), fuel leaks can lead to inflight fires.

Managing Fuel Anomalies/Emergencies

Managing Fuel Anomalies/Emergencies

-

Fuel Advisories:

-

Minimum Fuel:

-

Pilot Responsibilities:

- Advise ATC of your minimum fuel status when your fuel supply has reached a state where, upon reaching your destination, you cannot accept any undue delay.

- Be aware this is not an emergency but merely an advisory that indicates an emergency situation is possible should any undue delay occur.

- The term "minimum fuel" should be used on the initial contact after stating the call sign.

- "Salt Lake Approach, United 621, minimum fuel."

- Be aware a minimum fuel advisory does not imply a need for traffic priority.

- If the remaining usable fuel supply suggests the need for traffic priority to ensure a safe landing, you should declare an emergency due to low fuel and report fuel remaining in minutes.

- Fuel Remaining: A phrase used by either pilots or controllers when relating to the fuel remaining on board until actual fuel exhaustion. When transmitting such information in response to either a controller question or pilot-initiated cautionary advisory to air traffic control, pilots will state the APPROXIMATE NUMBER OF MINUTES the flight can continue with the remaining fuel. All reserve fuel SHOULD BE INCLUDED in the time stated, as should an allowance for established fuel gauge system error.

-

Controller Responsibilities:

- When an aircraft declares a state of minimum fuel, relay this information to the facility to whom control jurisdiction is transferred.

- Be alert for any occurrence that might delay the aircraft.

-

-

Emergency Fuel:

- Emergency fuel is a declaration of emergency.

- Declaring emergency fuel asks the controller for priority, going directly to the nearest airfield to land immediately.

-

Common Training Aircraft Fuel System Characteristics

Common Training Aircraft Fuel System Characteristics

-

Cessna 172:

- Two tanks hold 100LL aviation fuel (AVGAS).

- Each tank holds 28 gallons for a total of 56 gallons of fuel.

- Each tank has 1.5 gallons of unusable fuel for 3 gallons total unusable.

- Total usable fuel is, therefore, 26.5 gallons per tank or 53 gallons total.

- Each fuel tank is vented through individual vents.

- "Fueling to the "tabs" equates to about 17.5 gallons in each tank.

- Fuel is measured by 2 float type transmitters.

- Fuel pressure is measured through a transducer.

- Two tanks hold 100LL aviation fuel (AVGAS).

-

Piper Arrow:

- Two tanks hold 100LL aviation fuel (AVGAS).

- Each tank holds 38.5 gallons for a total of 77 gallons of fuel.

- Each tank has 2.5 gallons of unusable fuel for 5 gallons total unusable.

- Total usable fuel is therefore 36 gallons per tank or 72 gallons total.

- Each fuel tank is vented through individual vents.

- Fueling to the "tabs" equates to about 25 gallons in each tank.

- Tanks are integral

- Separate fuel quantity gauges exist for each tank.

- Fuel selector can be set to OFF, LEFT TANK, or RIGHT TANK.

- Two tanks hold 100LL aviation fuel (AVGAS).

Private Pilot (Airplane) Operation of Aircraft Systems Airman Certification Standards

Private Pilot (Airplane) Operation of Aircraft Systems Airman Certification Standards

- Objective: To determine whether the applicant exhibits satisfactory knowledge, risk management, and skills associated with safe operation of systems on the airplane provided for the flight test.

- References: FAA-H-8083-2 (Risk Management Handbook), FAA-H-8083-3 (Airplane Flying Handbook), FAA-H-8083-23 (Seaplane, Skiplane, and Float/Ski Equipped Helicopter Operations Handbook), FAA-H-8083-25 (Pilot Handbook of Aeronautical Knowledge); POH/AFM.

- Note: If K1 is selected, the evaluator must assess the applicant's knowledge of at least three sub-elements.

- Private Pilot Operation of Aircraft Systems Lesson Plan.

Private Pilot (Airplane) Operation of Aircraft Systems Knowledge:

The applicant demonstrates an understanding of:-

PA.I.G.K1:

Airplane systems, including:-

PA.I.G.K1a:

Primary flight controls. -

PA.I.G.K1a:

Secondary flight controls. -

PA.I.G.K1c:

Powerplant and propeller. -

PA.I.G.K1d:

Landing gear. -

PA.I.G.K1e:

Fuel, oil, and hydraulic. -

PA.I.G.K1f:

Electrical. -

PA.I.G.K1g:

Avionics. -

PA.I.G.K1h:

Pitot-static, vacuum/pressure, and associated flight instruments. -

PA.I.G.K1i:

Environmental. -

PA.I.G.K1j:

Deicing and anti-icing. -

PA.I.G.K1k:

Water Rudders (ASES, AMES). -

PA.I.G.K1l:

Oxygen Systems.

-

-

PA.I.G.K2:

Indications of and procedures for managing system abnormalities or failures.

Private Pilot (Airplane) Operation of Aircraft Systems Risk Management:

The applicant is able to identify, assess, and mitigate risks associated with:-

PA.I.G.R1:

Detection of system malfunctions or failures. -

PA.I.G.R2:

Management of a system failure. -

PA.I.G.R3:

Monitoring and management of automated systems.

Private Pilot (Airplane) Operation of Aircraft Systems Skills:

The applicant exhibits the skills to:-

PA.I.G.S1:

Operate at least three of the systems listed in K1a through K1l appropriately. -

PA.I.G.S2:

Complete the appropriate checklist(s).

Private Pilot (Airplane) Systems and Equipment Malfunctions Airman Certification Standards

Private Pilot (Airplane) Systems and Equipment Malfunctions Airman Certification Standards

- Objective: To determine whether the applicant exhibits satisfactory knowledge, risk management, and skills associated with system and equipment malfunctions appropriate to the airplane provided for the practical test

- References: FAA-H-8083-2 (Risk Management Handbook), FAA-H-8083-3 (Airplane Flying Handbook), FAA-H-8083-25 (Pilot Handbook of Aeronautical Knowledge); POH/AFM

- Private Pilot (Airplane) Systems and Equipment Malfunctions Lesson Plan.

Private Pilot (Airplane) Systems and Equipment Malfunctions Knowledge:

The applicant demonstrates an understanding of:-

PA.IX.C.K1:

Causes of partial or complete power loss related to the specific type of powerplant(s).-

PA.IX.C.K1a:

[Archived]. -

PA.IX.C.K1b:

[Archived]. -

PA.IX.C.K1c:

[Archived]. -

PA.IX.C.K1d:

[Archived].

-

-

PA.IX.C.K2:

System and equipment malfunctions specific to the aircraft, including:-

PA.IX.C.K2a:

Electrical malfunction. -

PA.IX.C.K2b:

Vacuum/pressure and associated flight instrument malfunctions. -

PA.IX.C.K2c:

Pitot/static system malfunction. -

PA.IX.C.K2d:

Electronic flight deck display malfunction. -

PA.IX.C.K2e:

Landing gear or flap malfunction. -

PA.IX.C.K2f:

Inoperative trim.

-

-

PA.IX.C.K3:

Causes and remedies for smoke or fire onboard the aircraft. -

PA.IX.C.K4:

Any other system specific to the airplane (e.g., supplemental oxygen, deicing). -

PA.IX.C.K5:

Inadvertent door or window opening.

Private Pilot (Airplane) Systems and Equipment Malfunctions Risk Management:

The applicant is able to identify, assess, and mitigate risks associated with:-

PA.IX.C.R1:

Checklist usage for a system or equipment malfunction. -

PA.IX.C.R2:

Distractions, task prioritization, loss of situational awareness, or disorientation. -

PA.IX.C.R3:

Undesired aircraft state. -

PA.IX.C.R4:

Startle response.

Private Pilot (Airplane) Systems and Equipment Malfunctions Skills:

The applicant exhibits the skills to:-

PA.IX.C.S1:

Describe appropriate action for simulated emergencies specified by the evaluator, from at least three of the elements or sub-elements listed in K1 through K5 above. -

PA.IX.C.S2:

Complete the appropriate checklist(s).

Aviation Fuel Case Studies

Aviation Fuel Case Studies

- NTSB Identification: ANC14CA014: The National Transportation Safety Board determines the probable cause(s) of this accident to be: The pilot's failure to adequately remove water-contaminated fuel during the preflight inspection, which resulted in a total loss of engine power

- NTSB Identification: CEN13LA354: The National Transportation Safety Board determines the probable cause(s) of this accident to be: The pilot's failure to identify the water contamination of the fuel system during his preflight inspection, which resulted in a total loss of engine power during the airplane's initial climb

- NTSB Identification: ATL03FA133: The National Transportation Safety Board determines the probable cause(s) of this accident to be: The pilot's failure to maintain control of the airplane during a VFR pattern for a precautionary landing, which resulted in an uncontrolled descent and subsequent collision with terrain. Also causal was the pilot's inadequate preflight inspection of the aircraft, which resulted in his failure to secure the fuel cap

- Pilot Workshops - Preflight Checklist?

Conclusion

Conclusion

- Safety is always a consideration and fuel handling is an especially regulated operation.

- It is advisable that the pilot remove all passengers from the aircraft during fueling operations and witness the refueling to ensure that the correct fuel and quantity is dispensed into the airplane and that any caps and cowls are properly secured after refueling.

- Read the National Fire Protection Association Standard for Aircraft Fuel Servicing for more information.

- Always visually check the fuel level in each tank during the preflight inspection and then compare it with the corresponding fuel quantity indications.

- The impact of misfuelling can be fatal - necessitating a pilot's attention, especially after a long flight.

- Within fuel-related accidents, fuel exhaustion and fuel starvation continue to be leading causes.

- From 2011 to 2015, an average of more than 50 accidents per year occurred due to fuel management issues.

- Fuel exhaustion accounted for 56% of fuel-related accidents, while fuel starvation accounted for 35%.

- Learn more here.

- When a split exists between fuel tanks, trim the ball into the low tank.

- Learn more about misfueling with AOPA's misfueling safety brief.

- The AOPA provides a chart that shows the dramatic effect of fuel mismanagement.

- Read about an actual fuel leak experienced in flight.

- Aviation fuel is constantly adapting, and the FAA is leading programs with the goal of sustained alternative fuels.

- For more information related to aviation fuel, see:

- Still looking for something? Continue searching:

References

References

- Advisory Circular (33.67-1) Engine Fuel Systems

- Advisory Circular (150/5230-4B) Aircraft Fuel Storage, Handling, Training, and Dispensing on Airports

- AOPA Air Safety Institute Safety Quiz: Fuel Awareness

- Federal Aviation Administration - Pilot/Controller Glossary

- AOPA - Fuel Management

- BoldMethod - How Simply Switching Fuel Tanks Led To This Accident

- CFI Notebook.net - Pilot Information Manual

- CFI Notebook.net - Powerplant

- FAA Safety Alert (067) Flying on Empty

- National Fire Protection Association (407) Standard for Aircraft Fuel Servicing

- Pilot Handbook of Aeronautical Knowledge (6-25) Fuel System

- General Aviation News - How Long Can Fuel Be Safely Stored?

- Simple Flying - How an Aircraft Fuel System Works

- AOPA - Fuel Management Resources